How to make a logging machine from the jigsik. Homemade Machine of Electrol Communication for Sawing: Drawings and Video

For rubber threads and drinking small parts from wood, plywood, plexiglas, plastics and other materials are used by jigsaws different designs and species. It can be manual ("Pioneer"), mechanical and electric jigsaws. Various magazines led the schemes of homemade logging machines with a drive that had an electric motor and even electric drills. How to make a homemade logging machine in this article.

With the help of a desktop jigsaw machine at home, you can make furniture, beautiful patterned shelves and a lot more. The mechanism allows you to cut smooth and winding parts from wood, plastic and dense foam materials. So that the self-made device fully satisfies the requirements, it is necessary to carefully choose the appropriate design.

Design and specifications

The device of any model of the electrol-sized machine necessarily comprises:

- saw

- crank shutter assembly;

- drive unit;

- saw tension device;

- desktop;

- auxiliary mechanisms.

The material being processed is stacked on the desktop. Some models are equipped with a rotary device changing the slope of the surface. To make it easier to make the material marking, graduation is applied to the surface.

The larger the size of the table, the longer the cut can be performed. On average, this indicator is 30 - 40 cm.

Drive power for homemade desktop It is about 150 W.

The crank-connecting unit converts the rotational movement of the drive into the reciprocating and transfers to the saw. On average, the frequency of oscillations of the pink per minute - 800 - 1000. The amplitude of the vertical movement is not more than 5 cm. Some models allow you to select the speed of movement depending on the properties of the material.

The pink of the hand-made jigsaw can work with wood, plastic thickness not more than 10 cm, having a length of up to 35 cm. For different types Materials and works of the peel change, their width is 2 - 10 mm.

The manual tension device is fixed with a pink for uniform sawing, it is a screw or spring springs.

Types of machine tools

Constructively, you can split all the logging devices:

- with lower caliper;

- with double caliper;

- on the suspension;

- with a degree scale and stops;

- universal.

The most common models with lower caliper. Their bed is divided into two halves: lower and upper. The top placed the cutting and cleaning module. In the bottom - the control module, an electric motor, a transmission mechanism and a switching toggle switch. Allows you to process sheets of material of any size.

Models with a double caliper are distinguished by the fact that on the upper half of the bed there are an extra rail. Such devices are good to create oversized parts. They are easier to install than the previous option. Both models allow you to process the material is not thicker 8 cm. The machine is equipped with an angle and height adjustment.

Machines on the suspension are not equipped with a monolithic bed, they are very moving. During processing, the cutting module is moving, not the material. The working module is usually attached with your own hands to the ceiling, so the material size is unlimited. The cutting tool moves manually regardless of the bed, creating very complex patterns.

Machines with a degree scale and stops are good for accurate works in drawings. The design allows you to prevent errors. Universal electrolybike devices can perform several operations associated with cutting: drilling, polishing, grinding.

Making a machine with your own hands

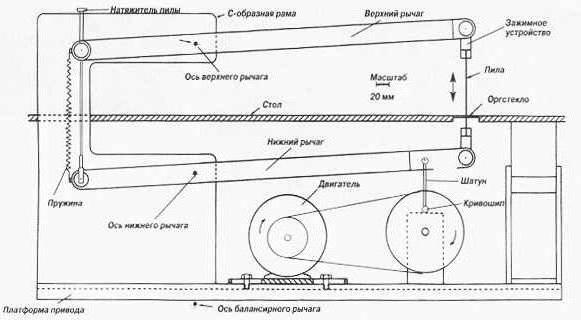

Drawing home-made desktop jigsaw: 1 - rocking bags (2 pcs.), 2 - earring (2 pieces), 3 - table, 4.6 - screws, 5 - traction, 7 - eccentric, 8 - base, 9 - Sereg axis, 10 - upper rocker, 11 - Rocker axis, 12 - lamb, 13 - cross-tension screw (2 pcs), 14 - tension screw, 15 - Rocking boards, 16 - lower rocker, 17 - Konts, 18 - two-double pulley, 19 - Intermediate shaft, 20 - rack sleeve, 21 - plate plate, 22 - bearing with lid (2 pcs.), 23 - electric motor pulley.

In the drawing of a tabletop made by your own hands, the number of nodes must be minimized, it is: a rocking chair with a fixed saw, a bed and an electric motor. You can take the engine from the old electric machine.

Owners of the manual electrolybishka are lucky. From the sheet of plywood you can make a stand and attach the jigsaw to it. For fastening the jigsaw, you will have to do holes at the base of the tool. The simplest model is ready.

Now about more complex and functional. The bed is made of plywood 12 mm, thick plastic or textolite. It is a base, a box for placing the engine and mechanisms, and a working table. On the other hand, we have a rocking chair with an eccentric. They are connected between themselves with a metal plate with sleeve bearing. The whole design on the screws is attached. For mounting the intermediate shaft prepare a pair of bearings. The two-axis metal pulley on the shaft is satisfied as close as possible, the screw connection is fixed. In the same way, you can make eccentric.

To change the amplitude of the rocking movement, four round through holes with threads removed from the axis on the eccentric flange are made on the eccentric flange. different distance. Changing the installation site of the screw, adjust the swing of the rocking movement. It is a pair of rocker from a tree attached to the hinges to the rack. The rear ends of the rocker contain through propyls, the tension screws are inserted into them. At the end of the front, the pill is fixed, moving due to metal hinges. Before attaching the pyline insert into the groove of the working surface of the table.

The mechanism for fastening the peel is very important. In the manufacture homemade device With your own hands, he should pay special attention. Plug-in rocker plates carry permanent loads when driving, so they are rigidly fixed and tied with screws with grovers piles. Fastening earrings should not be very compressed with screws, allowing you to move the hinge axis of the plate.

Rack rocking is advisable to make a solid piece of material. On the upper side, the groove was done for the rocker, the bottom end is cut out the opening in the form of a rectangle for the second rocker. To make it easier to cut holes, you can fold the rack of two parts.

Video about how to make a logging machine with your own hands:

Recently, I was very interested in the workman drinking a junk, I do not even know what it were. It all started with the fact that I needed to cut a few gear from plywood ...

And went went. At first I saw the gears manually, then I thought, swing the muscle with a manual junk is certainly good, but if you automate the process, it will be much faster!

So, for a start, let's get to know, this is a manual jigsaw for art sawning.

(All pictures in this article found on the Internet)

To cut the needle, they are thin as a wire, with sharp cloth. Previously, such pinks were sold in a pack of 50 pieces., Recently went to the store, so these "firemakes" them began to sell. For the evening you can break a couple of such pylons.

For drinking, we will also need a special table, it may be a board with a cone slot, screwed to the table with screws or clamps.

For the convenience of fastening the pylon in the machine, it is better to use a special device that will compress the loobs' contour, so you calmly change the pink without effort. With the help of wooden eccentric compression takes place.

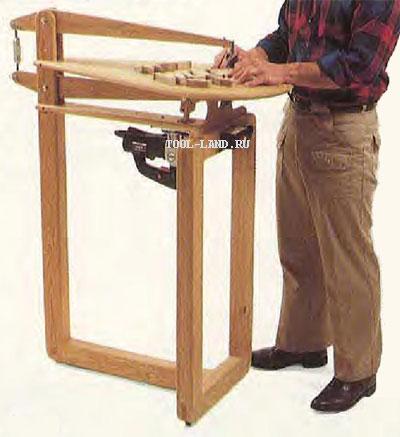

And now about automation. In the next photo you see the factory-type desktop electrolovka, you can find a sea of \u200b\u200bvarious modifications on the Internet. It is worth this thing is not very expensive, but even if you really want to find this in your city, but in principle, and nothing.

Industrial machines are certainly good, but I probably will treat them a couple of months and abandon this lesson, and in general this machine as I learned can be easily assembled from plywood and wooden bars.

The following photo uses an industrial manual electrolybiz and spring to return the saw.

So, we can easily assemble the desktop electroballs with your own hands at home. I personally did, but I have a special design, in this article there are no photos of my photos, but I will definitely lay out, as well as a video in work.

- Device and principle of operation

- Assembly instructions

- How to remake manual junk

- Machine from sewing machine

Desktop logging machine - equipment for cutting, drinking curly parts from various materials. Its feature is the possibility of cutting with the preservation of the integrity of the outdoor contour of the workpiece. Depending on which the pink is mounted on the design, the machine can process natural wood, its derivatives, plastic bases or metal.

The device is indispensable when performing construction and repair work, production of furniture, souvenir products. Often, equipment acquire for domestic purposes. Sometimes buying a factory unit is irrational: the electrolybiz can be made independently. The photo shows the design of the tool.

Device and principle of operation

The stationary factory sample includes a jigsaw desktop, a knot is fixed with a cutting element installed under the countertop the electric drive and the crank-connecting mechanism. The tension node is installed in the upper or bottom of the machine. Many models of aggregates allow you to cut the material under different angles. This is necessary for inclined cut. Often, for convenience on the rotary mechanism, the stops, the marking are applied. The length of the cut depends on the dimensions of the table, in most models is 30-40 cm.

The power of the electric jigsaw may be small. For household purposes, a capacity of 150 W is enough.

An important element is a cranked mechanism. It is responsible for the quality of the transmission of the rotational moment of the engine in a progressive return movement performed by the cutting element in a vertical position.

The standard logging tool is characterized by a frequency of oscillations up to 1000 per minute with amplitude 3-5 cm. In some samples, the speed of processing the various materials is adjusted. In most cases, it is installed on such a tool to 35 cm long, which allows you to cut the parts with a thickness of up to 10 cm.

In order for the cutting element to serve for a long time without breakdowns, cracks, it is necessary to ensure that it is optimal tension along the entire length. This uses screw and spring springs. As an additional option, the factory apparatus is provided for an air pump to remove sawdust from the cut line. A block with a drilling installation is useful, but for each additional node must be paid.

Assembly instructions

The logs is made from the refrigerator compressor, ordinary drill. Cut the cutting canvas in motion using the engine from washing machine. Another option is the use of manual electrol lumps, old sewing machines. The figure shows the design drawing.

How to remake manual junk

First of all, the table is manufactured. For this, a sheet of thick plywood or metal is used. It drinks through holes for the cutting cloth, fasteners. Through them, the manual aggregate placed on the bottom is fixed to the supporting structure. Next, the logging table is fixed on any sustainable wooden table. Guide rails are added.

If necessary, the machine can be quickly disassembled.

The standard device is equipped with springs providing the beer the required tension level. Do not do without a rocker, one of its edge is under the tension of the springs, the second provides the fastening to the cutting element of the jigsaw machine. You can hp the cloth and between the two guide rollers.

Before starting work on a homemade jigsaw, a pendulum move is definitely disconnected.

Sewing machine

The jigsaw from the sewing machine contains a regulator of a pink stroke, provided by the speed switch on the equipment.

For the manufacture, remove the mechanism of weaving threads. In most constructions, it is placed below. The bolts are unscrewed, sprinkle, remove the drive shaft leading to the node of the weaving of the threads.

Then the upper protective panel opens, the grooves are expanding, according to which the needle moved to the width parameters. Saws for the jigsaw are slightly modified: clipped according to the size of the longest needle itself, which could be installed on the machine. In order not to make an adapter to fix the cutting element on the seat, the upper incisors are sharpened, they make an acute bottom of the canvas. A reserve is installed in the needle holder. After that, they start drinking blanks.

The logging machine allows you to quickly and effectively drink wood. It consists of a working surface, racks, motor and spindle node. Some devices are made on stands. The clamps are often installed in the side of the working surface. It is also worth noting that the models differ in power. The manufacture of a logging machine can only be carried out if the instructions are followed.

Desktop devices: specialist reviews

If you believe feedback, then make a desktop modification is very simple. First of all, the stand is harvested under the working surface. Its width should not exceed 30 cm. Motor is more expedient to pick a single-phase type with a limit voltage of 220 V. The homemade logging machine (bench-top) on average produces a working frequency of 55 Hz.

Professional reviews suggest that the tees is better to use from steel, if desired, you can cut them yourself. The carriage is installed on the spindle node that is attached to the rack. Many models will apply a retainer, which plays the role of stop. To secure the punch, a small screw is applied.

Models on legs

If necessary, you can make this with your own hands. Modifications drawings include frames of different sizes, and spindle nodes are usually used with guides. Many models are made on a wide bed. The legs can be installed from the tubes. There are also machines with plates. After the cutout of the working platform, the spindle node should be done.

If we consider devices with control blocks, then the model will require the controller. Motor It is more expedient to apply a collector type on 220 V. TiSi on the jigsaw machines installed a rotary type. The direction must be welded to the edge of the plate. The pink in this case should be securely fixed. Optimal height The spindle node is 2.2 cm. At the end of the work, it is important to engage in installing the power cable and the connection of the equipment.

Reviews about devices with a wide frame

Professionals are able to assemble the logging machine with their own hands. Drawings of devices indicate the presence of broad stops. However, first of all it is necessary to install the bed. If we consider a simple machine, then the fixator for modification can be selected small lengths. Professionals indicate that two racks are enough for the model. A welding inverter is used to assemble the machine. The spindle node directly is installed in the central part of the working platform. A hole for the peel can be made of cutter. It is also worth noting that experts do not recommend using two-phase engines.

Compact modifications

Adhering to the instructions, you can collect a compact logging machine with your own hands. Drawings of devices include double racks and narrow frames. Stannes are used with a low profile. Many models have a spindle knot without holder. In this case, the guides are set by small length. For self-assembly Models are recommended primarily to select a quality frame.

Additionally, the retainer is soldered under the work plate. To reduce the level of vibration, you can use the lining. For its fixation, ordinary glue is applied. The filling for modification should be selected with a small thickness. The optimal distance of the installation of the central node is 14 cm. In this case, the platform width is 17 cm.

Lobsiki for 2 kW

If you wish, you can make this logged machine with your own hands. Drawings for assembling modification is very simple. As a rule, the frames are used with a width of 35 cm. The plate thickness should be about 1.5 mm. The hole under the pedal must be made before installing the central node. If we consider models without stops, the frame is used with a low profile. It is also worth noting that the spindle node is expedient to install on the lining.

To reduce noise, the casing is used. Many models use several stops. In this case, the node is set at height from 10 cm. The pylon is better fixed on the plate. Clamp You can use a screw type. After fixing the central node, the motor is put. To modify this type, a device with a single-phase block is suitable.

Models for 3 kW

For 3 kW, the desktop electrolybiz is pretty simple. Experts recommend using racks with wide stops. Fixators need to be installed only after the central node. Pink for modification can be chosen by 1.2 mm. Some experts hole do after installing the frame. In this case, the supports are soldered around the table.

This is further important to estimate the size of the spindle. Motor is more expedient to use with a protection system and a casing. It is also worth noting that collector devices that work at a frequency of 45 Hz are very popular. They have low energy consumption, and they do not overheat. To fix billets apply holders. The optimal height of the spindle is 15 cm. It is also worth noting that there are models with tuning plates. A flywheel is used to control the rack. To install the control unit, there is a regular controller.

How to make a device for 5 kW

Preparing several stops and you can make a logging machine with your own hands. Professionals indicate that 5 kW models are well suited for longitudinal cutting. Before starting work, all required tool. We will need a saw, as well as a welding machine and cutter. Frame for the logging machine is more expedient to collect from steel plates with a thickness of 1.3 mm. For the motor you need to immediately foresee. Stannes in devices are installed high profile.

At this stage, you can immediately cut the hole under the pipe. The plug assembly must be mounted on the top of the plate. Additionally, it is worth noting that a big holder will be required for the peel. If we consider a simple model, then the racks can be installed on the sides of the frame. Tisi used turning type. At the top of the frame, there is a rack. A small casing is selected for the motor. On average, the width of the frame should be 35 cm. If we consider professional models, they use regulated clamps.

Two pin cells modifications

How to make a logging machine with your own hands? The model with two pinoles is collected only on a wide frame. First of all, the plates are cut under the face. If we consider the desktop modification, then the control unit is more expedient to install in the upper part of the device. The optimal frame width is 45 cm. At the same time, the spindle node is installed behind the stops.

For racks should be provided in many models used transmission blocks. In this case, the motors are only a collective type with a frequency of 30 Hz. The pedel is installed standard in the holder. The optimal height of the spindle node in the models is 35 cm. Pinoli for adjusting the beds are used with flywheels.

Models for three pinoles

On the basis of a single-phase motor, it is easy to make this with your own hands. Tools should be harvested in advance. Many models are equipped with frames for four stops. They have a big length and high profile. It is also worth noting that spindle nodes are selected from at the beginning of work it is very important to calculate the length of the frame. If we consider conventional spindle nodes, then the rack is harvested with a small length.

The central support must withstand heavy loads. A welding inverter is used to install the plates. The motor will require a casing, which will significantly reduce the noise level of the device. Saw for modifications of this type is suitable for 1.2 mm. With a power of 3 kW, the device for three pin will produce a frequency of 55 Hz. For fixing the flywheels you need brackets.

What to do when you need a jigsik, but there is no need to buy it? You can make a jigsaw with your own hands. There are many ways to manufacture or repair such a tool. Consider the simplest and affordable of them.

Hand Lobzik - Just, Quick and Available

How to make a jigsaw quickly from affordable and inexpensive materials? Here is the easiest way.

List of tools and materials:

- plywood sheet (10 mm);

- plywood sheet (4 mm);

- steel sheet (2 mm);

- bolts and nuts;

- drill;

- chisel;

- grinding paper;

- file.

The base of the manual jigsaw is a bracket, it should be prepared from plywood sheet (10 mm). Next, it is recommended to make thickening for the handle of the tool from a thinner plywood (4 mm). These thickening should be pasted on the handle on both sides, which will ensure further more convenient. The bracket and the handle are well treated with grinding paper and a file. From the steel plate must be cut off with chisel, and then clean the clamping sponges with a file. After that, in sponges, drill a drill of the slits, and then cut with a sharp chisel of notches inside the clamping sponges. In the left clamping sponge, modify the slot for the bolt, for this you need to make a thread. Sponges attach to the bracket, then screw the bolts into the left clamp, securing them with nuts.

Back to the category

Desktop Lobzik: Two manufacturing options

The desktop can be made both new and with the help of refinement or repair of remedies.

Production of a new desktop mechanical jigsaw will require the presence of such tools and materials:

- pipe Dulely;

- plastic base;

- clamps;

- screws;

- copper sheet;

- drill.

First you need to prepare a framework, it is better to use a duralum pipe for this purpose. When making a frame, it is necessary to provide a passage to which the cord will be laid, providing power supply. Copper sheet should be taken to make a P-shaped frame, which will be subsequently needed to attach to the carcass itself. In place of a frame connection with a knob jigsaw frame to fasten with screws. In a plastic basis, drill with a drill hole for a sawdill, as well as slits for fasteners. On the prepared plastic, fasten the jigsaw so that the feck passed through the hole. Using clamps, attach the finished tool to a flat surface, for example, to the table.

A manual device made on the basis of a sewing machine is the perfect option if the repair of the sewing machine is not as important as the manufacture of such a tool. List of tools and materials:

- sewing machine (you can use both foot and manual model);

- pink;

- feet;

- drill.

Having twisted the bolts at the bottom of the sewing machine, you should remove the entire system of working with the thread. Next, knock out the metal fastener and remove the actuator's actuator actuator. The panel closing the details of the sewing machine is easy to remove, if you unscrew another 2 bolts. Gently remove the needle. The slot for the needle requires a small repair - it should be expanded so that the Pillet can be placed in it. To do this, it is better to cut the hole with the help of the leg, focusing on the size of the peking itself. After that, it is necessary to adjust its size to the highest possible size of the needle, cutting the upper part of the saw. After stepping up the upper teeth using a file, and the lower part on the tip can be started up to the next step. The prepared pip should be put on the place of the former needle - to the needle holder. After that, you should turn the wheel and check:

- so that the saw did not come into contact with the panel and with the presser foot;

- so that in the upper position of the plywood passed freely under the saw;

- so that the material takes place smoothly.

Such a junction is suitable in order to work with materials from plywood, balz wood and plastic, and if you use an electric machine, it turns out the jigsaw electric.