Installing a plastic window - step-by-step instructions for self-application. Installation of plastic (pvc) windows in accordance with GOST Regulations for the installation of pvc windows

Plastic windows have advantages over wooden ones and have earned popularity among the population. The article provides the procedure for installing plastic windows and video material (at the end of the text). The main provisions of GOST, including instructions for carrying out such work, are given. Also, some recommendations and explanations for the construction of windows are given. The description is given on the example of replacing an old wooden window; in new houses, dismantling is simply not necessary.

Sizes and selection of windows (GOST)

Dimensions of windows for different types houses are very different, but in the same house they can differ by several centimeters. That's why it is important to determine the correct dimensions of the product that determine its value.

Comment! The gap between the edge of the window frame and the wall should be 2-6 cm, if it is larger, the window opening should be reduced by laying bricks (stronger structure) or foam.

Windows are produced standard sizes, which depend on the type of house - panel, brick, "Khrushchev", etc. These are windows of the series P-46, P-44, -44T, P-3, -3M.

If standard windows are not suitable, you can always make a custom-made window of any size. Moreover, there will be no loss in cost.

By the type of glazing (double-glazed windows), windows are of various types:

- two-chamber - preferable and cheaper;

- three-chambered, maybe more;

- triplex (multilayer) - do not give fragments;

- with tempered glass - give small "blunt" fragments;

- energy saving, noise protection, sun protection.

PVC windows are available in three classes:

- economy class - KBE, Montblank, Novotex;

- standard - Rehau, Shueco, Vera;

- VIP class - Shueco Corona, Salamander, etc.

Preparation of a window opening

First you need to prepare the window. Take out the glass unit and remove the sash. Drill several mounting holes in the bag. For a two-leaf window, 2 at the edges and one at the top and bottom are enough, for a three-leaf window there may be more. Next, you need to remove the old frame (if any), clean the surface from dirt and align. The frame is attached to the opening in three ways:

- special brackets;

- self-tapping screws for concrete;

- anchor bolts (the most common and convenient).

The depth of the holes for the bolts is 4-6 cm, depending on the wall, for slotted bricks - the maximum.

Attention! If there are strong winds in the area, you should consult with a window wind load specialist, especially on upper floors.

Materials:

- Polyurethane foam - double-leaf window - 3 cylinders.

- Liquid plastic- 1 tube is not multiple windows.

- Water-based paint - 2-3 l / window.

- Dowels - 660 mm - 15-20 pcs.

- Self-tapping screws.

- Anchor plates or anchors - 4 per window.

The exact amount depends on the type of window.

Installation procedure for plastic windows

Practice shows that window mounting defects may appear during operation. It is characteristic that immediately after the end of the work, these errors are not noticeable, therefore, when installing plastic windows with your own hands, you need to be very careful.

The installation of various window options is somewhat different from each other, but the most common stages are typical for all windows. These procedures are described below.

Ventilation of the room with PVC windows

When choosing plastic window special attention should be paid to the ventilation of the room.

The fact is that the windows are almost completely airtight and ventilation is possible only by opening the window sashes, which leads to drafts. Wooden windows do not have such a defect. The way out is to install windows equipped with ventilation valves, for example, "Aereko".

The features of the valve include the absence of extraneous noise from the street. One valve provides ventilation for a room of approximately 50 m2. The ventilation is carried out continuously, with an adjustable flow rate.

Thus, the installation of plastic windows is possible on their own.

If earlier you or your acquaintances used the services of firms for the installation of double-glazed windows, then you know that the installation can be normal and in accordance with GOST. The second option is more expensive, but if all the requirements are met, then the quality will be much higher than in the first (for more details about the norms, see GOST 30971-02).

Consists of several stages.

Note! The manufacturers do not give a guarantee if the measurements were not carried out by their employees. If installed incorrectly, the windows will soon begin to freeze, and if even the slightest mistake was made in the calculations, then the structure simply will not enter the opening.

Nevertheless, if you study all the subtleties of the process, then there will be no difficulties during installation. Moreover, you can save a decent amount of money this way.

Video - Installation of PVC windows in accordance with GOST

Stage 1. Measurements

In most apartments, there are openings without a quarter.

Note! A quarter is inner frame 6 cm wide (or ¼ brick, hence the name), preventing the window from falling out and reinforcing the structure as a whole.

If there is no quarter, then the frame will be installed on the anchors, and the foam will be closed with special cover strips. Determining the presence of a quarter is quite simple: if the inner and outer widths of the frame are different, then there is still a quarter.

- First, the width of the opening is determined (the distance between the slopes). It is recommended to remove the plaster to make the result more accurate.

- Next, the height is measured (the distance between the slope above and the window sill).

Note! Measurements must be repeated several times and take the smallest result.

To determine the width of the window, two mounting gaps are subtracted from the width of the opening. To determine the height, the same two gaps plus the height of the profile for the stand are subtracted from the height of the opening.

The symmetry and straightness of the opening is checked, for which a mounting level and a plumb line are used. All defects and irregularities must be indicated in the drawing.

To determine the width of the drainage, add 5 cm for the bend to the already existing drainage. Also, the width of the insulation and cladding is taken into account (subject to the subsequent finishing of the facade).

The dimensions of the window sill are determined as follows: the size of the departure is added to the width of the opening, the width of the frame is subtracted from the obtained figure. With regards to the departure, then it should overlap the heating radiator by a third.

Note! are measured at the end of the installation.

Stage 2. Order

After measurements, the finished drawing should be referred to the window manufacturer, where all the necessary fittings will be selected. It is worth remembering that installation can be performed in one of two existing ways:

In the first option, you will have to pull the bag out of the frame, insert it into the opening and install the glass back. In the second case, the entire structure is attached as a whole. Each option has its disadvantages - if you pull out the package, then it can; and vice versa, if the window is put assembled, then it can be damaged due to its heavy weight.

Prices for a popular line of windows

Stage 3. Preparation

This stage of installation begins only after the delivery of the ordered windows. First released workplace, all furniture is covered with plastic wrap (there will be a lot of dust).

Step 1. If required, a double-glazed window is removed from the window. For this, the glazing bead is slightly pry off with a staple and pulled out. First of all, vertical glazing beads are removed, then horizontal ones. They must be numbered, otherwise gaps will form after installation.

Step 3. The bolts are unscrewed after the plugs are removed from the awnings. The handle is turned to "ventilation mode" (in the center), the window is opened slightly and removed. Only the frame with imposts remains.

Note! Mullions are special jumpers intended for dividing the sashes.

Then you need to make a markup for the anchors and make holes along it - two from the bottom / top and three on each side. This requires anchors ø1 cm and a drill of the required diameter.

If the material from which the walls are made is loose (for example, cellular concrete), then the fastening is performed using anchor suspensions. The latter should be fixed to the wall and frame with hardened self-tapping screws (eight pieces each).

Note! To avoid the formation of a thermal bridge in the window sill profile, it should be filled in the day before installation. So the element will not freeze.

Stage 4. Dismantling work

This procedure is recommended to be carried out immediately before the installation of a new window. In most cases, the old ones are thrown away, so the structure can be torn out together with the mount, and, if necessary, the frame can be sawed.

Step 1. First, the sealant and thermal insulation are removed.

Step 3. The window sill is removed, the cement layer under it is peeled off.

Step 4. The adjacent surfaces are treated with a primer (by the way, many installers forget about this). In the case of a wooden opening, a layer of waterproofing material is laid around the perimeter.

Note! Installation can be carried out at a temperature not lower than -15ᵒС. The polyurethane foam must be frost-resistant.

Stage 5. Installation of a plastic window

Step 1. First, wooden wedges are placed around the entire perimeter, a window is installed on them (this will make it easier to align the structure), only after that it is attached to the wall. The underlays can be left as additional fasteners.

Step 2. The absence of a support profile can be considered a gross violation of GOST standards, since it is not only needed for stability, but also makes it possible to install an ebb with a window sill. In the absence of a profile, they are attached directly to the frame, which violates its tightness.

The correct position of the stand profile is shown in the diagram.

Step 3. Next, the evenness of the window is checked in three planes, for which a mounting level and a plumb line are used. Typically, traditional bubble levels are not suitable for this due to insufficient measurement accuracy, so it is better to use.

Step 4. If the window has risen evenly, then it is fixed with anchors. To do this, a wall is drilled with a perforator through pre-prepared holes in the structure (about 6-10 cm). The lower anchors are fixed (not completely), the evenness of the package is checked again, after which the remaining points are attached.

Note! The final screed is made only after the final check. Do not tighten too much, otherwise the structure will "skew".

Prices for polyurethane foams and nail gun cleaners

Polyurethane foam and nail gun cleaners

Stage 6. Drainage

Outside, an outflow is attached to the support profile with self-tapping screws. The joints are carefully sealed with sealant to prevent moisture penetration into the structure.

The edges of the low tide are recessed into the walls by several centimeters, having previously made recesses using a perforator.

Note! The bottom slot is also sealed before installation.

Step 7. Assembling the window

After fixing the anchors, the glass unit is inserted back.

Step 1. The glass is inserted and fixed with glazing beads (the latter should snap into place, for which you can lightly tap them with a rubber mallet).

Step 2. The leaves are opened, their tightness is checked. In the open position, arbitrary opening / closing of the sash cannot occur if the window is installed level.

Step 3. The assembly seam is closed on the sides. Polyurethane foam will provide high-quality waterproofing and prevent glass fogging. Before and after sealing, the joints are sprayed with water to improve polymerization.

Note! The seams are filled no more than 90%, otherwise the structure will "lead". If done correctly, the foam will come out a few centimeters after drying.

Step 4. The perimeter of the window is glued with a special vapor barrier tape, and a material with a foil surface is used from below.

Stage 8. Installation of the window sill

Step 1. The sill is trimmed so that it fits into the opening and at the same time rests against the lining profile. There remains a small gap (about 1 cm) for thermal expansion. In the future, the gap is hidden by plastic

Step 2. Wooden wedges are placed under the windowsill. It needs to be laid with a slight slope towards the room, and then applied with something heavy for a while, until the foam dries. Additionally, the window sill can be fixed with anchor plates.

Video - Installation instructions for plastic windows

conclusions

Now you know how plastic windows are installed, so you can safely get down to work. The final check of all elements can be carried out only 24 hours after the end of installation (then the foam will already "set").

The described technology is quite applicable to, although there are also some nuances - such, for example, as installing a parapet to create a partition.

Find out how to do it right in our new article.

In addition to the cost of a plastic window, intermediary companies also include installation and delivery services in the final amount. In order not to spend thousands of rubles and save money, you can install a plastic window yourself. In that step by step master class we will teach you how to properly dismantle the old window and prepare a new one for installation, taking into account the installation technology in accordance with GOST.

Step # 1: Dismantling the old window

In our case, we are dismantling the plastic window. The old wooden window is removed from the opening in the same way, so there should be no problems at this stage. For dismantling, we need the following set of tools: a hacksaw, a crowbar or crowbar, a chisel, a spatula, a nail puller, a hammer drill, a screwdriver (Phillips screwdriver).

First, we remove the slopes. If they are made of PVC panels, clean the seams from the sealant or glue. Take a chisel or flathead screwdriver and remove the decorative panels. If the slopes are plastered, use a chisel and hammer to remove the layer of plaster. Remove the sashes from the hinges. In plastic windows, remove the decorative top plate, press the stem with pliers. Remove only the cover plate from the lower hinge, lift the sash up.

With wooden windows it is more difficult. Often the hinges are painted over with paint or completely rusted, then we knock out the stock by hand with a hammer or tear off the sash from the frame with a crowbar or crowbar.

We remove the glass unit. We take a spatula, insert it end-to-end with the glazing bead, which fixes the position of the glass unit, pry it off and remove it. We remove all 4 glazing beads that hold the glass unit. The last one is to remove the upper glazing bead. We take out the glass, remembering to put on tight gloves so as not to get hurt. To safely remove glass from the frame, you can use special suction cups.

We pass to the windowsill. Remove the old concrete window sill with a hammer and puncher. Our windowsill is plastic. Since it is in good condition, we carefully take it out and peel off the old layer of polyurethane foam. It can be easily dismantled with one light jerk upwards. Remove the ebb, unscrew the fixing screws with a screwdriver or screwdriver.

We take a hacksaw and cut an old layer of polyurethane foam with a tool around the entire perimeter of the window. We remove the fasteners. We unscrew or pull out the anchor plates or self-tapping screws for concrete with a nail puller.

After all the stages of dismantling, the frame remains in the opening. We carefully take it out, preferably with a partner. It is more convenient to remove the wooden frame in parts, first sawing the impost (frame divider), the lower part, and then remove the sidewalls and the upper crossbar.

Step # 2: Attach the new window frame to the opening

Before starting work, we remove dust, debris, pieces of concrete on the slopes, large nails. For better adhesion of the polyurethane foam to the base, cover it with a primer over the entire width. We insert the frame into the window opening and try it on, after removing the sashes and double-glazed windows.

We put support pads under the corners and impost connections of the lower frame profile. We make sure that on both sides the frame goes over a quarter of the window opening. We use mounting wedges, not pieces of wood or old window frames. The gaps between the frame and the slopes should be about 2 cm at the sides and bottom and at least 1 cm at the top to fill the space with polyurethane foam.

Checking possible deviations horizontally and vertically level.

If you install metal-plastic window according to GOST, we recommend sticking PSUL tape along the outer perimeter of the frame. It will protect assembly seams from ultraviolet radiation, moisture penetration, mold and mildew formation, and create reliable sound insulation. Along the end with inside frames (on the sides and on top), we glue a double-sided vapor barrier tape. It removes excess moisture outside and does not allow it to penetrate from the outside, and provides good ventilation. The tape to be applied should be wider than the seam for overlapping.

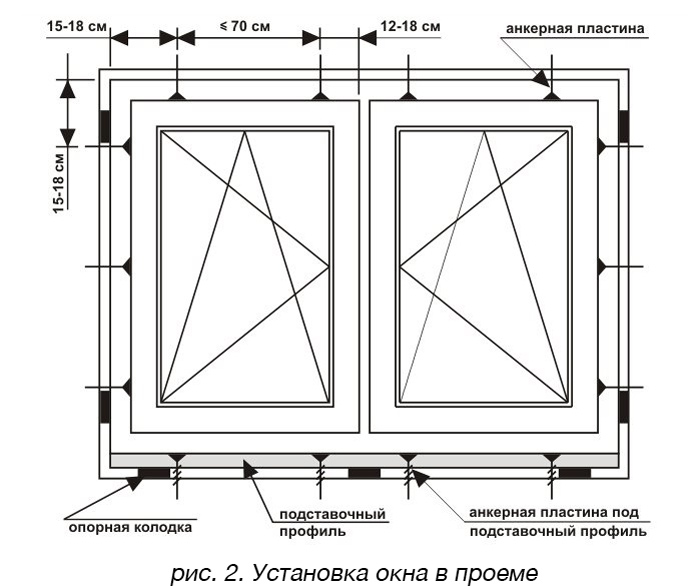

We drill holes in the frame and wall for the pins. We retreat from the corners of the frame in each direction by 15-18 cm and check the level deviations. It is difficult to do everything yourself. Therefore, one person works with a puncher, and the second holds the level. The distance between the fasteners on the frame should not exceed 70 cm.

On the lower part of the frame, we retreat 12-18 cm from the dividers (imposts) on each side and make holes for the pins. We do the same at the top of the frame.

We insert pins into the holes, we do not tighten them before the end. We check the structure again by level and finally fix the fasteners. We put decorative caps on the hats.

Step 3: external waterproofing and foaming of the seams

For waterproofing the external assembly seam, we lay a vapor-permeable tape under the ebb. It will protect the seam from moisture and provide adequate ventilation.

We lay the tape along the entire length of the window opening. Remove the bottom base and attach it with the adhesive side to the base. We fix the drainage. In our case, we are using an old sample with adjusted dimensions. When installing a new ebb, we measure the distance between the quarters. According to the measurements made, we cut off the desired length of the low tide. We retreat 2 cm on each side and cut off the edge. We insert the ebb into the groove and fix it with self-tapping screws on the support profile, drilling 3-5 holes for fixing.

Standard installation

Installation of plastic windows assumes adherence to GOST standards. Home owners do not always prefer to install windows according to all the necessary rules and regulations.

Installation diagram of a plastic window.

Experts strongly recommend that all residents adhere to these rules, especially those who have office space, shops, and various public institutions at their disposal. Most buyers are sure that the quality and reliability of the entire structure depends on the profile. But apart from this, assembly and, accordingly, installation plays a key role. Sometimes the owners who hire specialists do not think about whether the installation will be done in accordance with GOST. The manufacturer of the profiles always indicates that the assembly should be done in this way, but the installer may not follow these rules.

Installation diagram of a plastic window.

Installation in accordance with GOST is optional. This is more of a recommendation. If the homeowners decide to install windows, guided by the requirements of the standard, it is necessary to invite qualified employees, preferably from a large construction company. A contract is concluded with this company, which includes a certain point, which indicates that the installation will be carried out exactly in accordance with GOST.

When buying, the seller must select the appropriate profile that will meet the specific conditions. The structure should be checked for optimal air exchange and heat transfer, for the level of sound insulation, dust penetration, etc. As a rule, well-known supplier companies have certificates that the window structures have passed the necessary checks. Accordingly, it is better to purchase goods from them.

Basic requirements during installation

It is important to take into account the fact that most problems with plastic windows arise if the installation is done incorrectly. Therefore, if you decide to install plastic windows, you should not save on the installation process. Today in Russia there is GOST 30971-2002. The rules given are for correct installation... First of all, the GOST indicates the types of profiles, also examples and different options mount. During the installation process, it is important to follow certain rules: there should be no cracks, openings. This is necessary for isolation from the cold. In the places where the window is fastened vertically and horizontally, three seams are made: internal, external and middle. Moreover, in order to properly mount the window, it is necessary to take into account the expansion of the plastic when heated.

Window installation scheme in the opening.

It must also be remembered that when choosing, one should be guided by sanitary standards and tightness standards. The optimum will directly depend on this. temperature regime and humidity level. In order to find out such standards, it is necessary to consider the requirements of SanPin 21.2.1002-00, where the norms of ventilation and heating in a dwelling are prescribed. If you do not follow these rules, there may be a risk of infection with fungus or mold, this can occur due to excessive moisture levels.

It should be noted that the installation in accordance with GOST is a guarantee of your safety and the favorable functioning of the window structure. In addition, installation according to the required standards ensures a favorable microclimate in the house.

When installing, the joints must be positioned in 3 levels. The first is able to protect the room from the penetration of precipitation and water. The second (inner) level must protect against the penetration of vapors. The third level is done using construction foam. The types of walls are also spelled out in the standards, which must also be taken into account. You need to know all the installation rules. They are convenient for guiding both during the purchase and during the installation process. It is worth repeating once again that you should buy only high-quality, certified products. The seller must necessarily provide you with documents where all technical features products.

Installation requirements

The quality certificate must be awarded not only to the company that sells the windows, but also to the one responsible for the installation. It is important that qualified specialists undertake the installation of the structure. The emergence and implementation of the certification system will bring the business to a high level. Today, the buyer makes high demands on the quality of structures and service in general.

Before installation, it is necessary to make all the necessary measurements by comparing them. It is important to know what loads the structure can withstand, the wind load is determined. From this it is concluded whether additional installation of the frame with metal plates is necessary. Some windows may leak air. In this case, the frames are installed to normalize the thermal insulation.

Window installation diagram.

It is important to carefully prepare the room before installation. It is necessary to remove all extraneous things in advance. It is recommended to cover the furniture with a wide cloth or film. Household appliances in the room must be isolated from dust. First, pull out the sash and carefully remove the frame. The opening must be free of unnecessary parts, all slopes are checked using a level.

After the structure is delivered, it is necessary to separate the frame and glass units. The frame is inserted into the opening using special wedges. Then you should mark the frame and determine how it will be located in the opening. After the frame is fixed. For this, anchor bolts and self-tapping screws are used. The glass unit is fixed with glazing beads. In order to make all measurements correctly, you need a laser ruler. It is important that the entire structure is firmly fixed. For this, there are certain rules, for example, the distance between the points of the fasteners should be about 70 cm. The distance to the fasteners from the inner corner should be a maximum of 15 cm.

The structures of the walls are different from each other. The choice of fasteners depends on the characteristics of the wall. Basically, fastenings are made using anchor bolts, anchor plates and self-tapping screws. Most practical way- use of anchor plates. It is important to correctly install the slopes that cover the opening between the profile and the wall. For installation, remove the remnants of the plaster from the old window, level the unevenness with a putty.

Instruments

- hammer;

- puncher;

- a crowbar for pulling out old nails;

- building level;

- polyurethane foam and a construction gun for working with it.

The installation of plastic windows should be carried out only by experienced specialists, it is advisable to carry out the installation, following all the requirements and rules of GOST. In the firms that are engaged in the installation of plastic windows, there are quality control departments, where you can contact if you have problems with the installation.

Load more

Before the start installation works it is necessary to completely free the window opening and the space next to it:

- remove everything from the windowsill,

- remove the curtains,

- clear the approach to the window by moving the furniture at least 1.5 meters away from the window.

Protect the room from dust and dirt by covering the floor and furniture with cloth or thick oilcloth.

For ease of installation, connect the 220V power supply through the extension cord, prepare garbage bags.

Dismantling the old frame

After the room is ready for the appearance of dust and debris, they begin to dismantle the old window frame.

The sash is removed from the window. Dismantle window frames... If necessary, dismantle (knock off) the slopes.

The old window frame is dismantled, and, as a rule, it is seriously damaged. If you want to use old windows, for example, in the country house, you should stipulate the option of keeping old windows when ordering.

The old ebb, the old window sill is being dismantled.

PVC window installation

The sashes are removed from the plastic window, the double-glazed window is removed. A window frame is inserted into the prepared opening and fixed on anchor bolts or mounting plates. In this case, it should be strictly observed that the frame is level, and not along the opening (in houses there are often cases when the horizon line of the window opening is far from ideal, the frame should also be level vertically). Otherwise, the window will not function properly.

The gaps between the wall and the frame are foamed with polyurethane foam. The foam serves both as an insulating function and as a fastening element. The overall result largely depends on the quality of this stage of installation. The foam should be applied evenly and fill all recesses and cavities in the opening, taking into account the expansion rate of the foam.

The installation of a plastic window in most cases means that a new window sill and a new ebb will be installed along with the new window. An exception is the case when the apartment (house, room) is renovation work and the sill can be installed on its own.

If the window to be mounted opens onto a balcony (as in this case), then it is quite expedient and functional to install a window sill instead of an ebb (from the outside of the window).

If you have a good old ebb tide, then you can save it for a new window, but in this case it will need to be restored (restored) - a paid service, the cost of which is slightly different from the cost of a new ebb tide.

The window sill is cut out under the opening and attached to the window (to the support profile). If the opening under the windowsill is small, then it foams. Otherwise, it is necessary to masonry or seal the opening with mortar. When installing a window sill (window sill), control that it has a slope from the window within 5 degrees, and the overhang beyond the inner surface of the wall is no more than 60 mm.

When installing the window sill, it should be borne in mind that its edges go beyond the finish inner slope to a depth of at least 15-20 mm.

Advice: when choosing the width (depth) of the window sill, it should be borne in mind that the window sill is "recessed" by 2 cm under the window frame, therefore the width of the installed window sill will be 2 cm less)

All gaps between the window and the opening are filled with foam, and when it dries, they are isolated. The outer layer of insulation is designed to protect the insulation layer (which is the foam layer) from moisture penetration into it, as well as from destructive sun exposure.

So, the main part of the work is finished. However, for finishing the opening lacks slopes (which are both a decorative addition, under which you can hide the mounting foam, and a functional element that increases the thermal insulation and sound insulation of the window opening). Plastic slopes will give the window a finished look, moreover, it is the best combination with plastic windows.

Installation of plastic slopes

Plastic slopes are installed on the same day with a window for panel and block houses and on the second day for Stalinist houses.

Either a Belgian sandwich panel (in the picture) or German VEKA plastic slopes with removable platbands are used as slopes.

The differences between the various plastic slopes are not significant, but you should be aware of them.

The Belgian sandwich panel can be installed at dawn (not at right angles to the window), which visually enlarges the window opening. The choice of VEKA plastic slopes is justified for more accurate gluing of wallpaper with already installed slopes. Thanks to the removable casing, the edges of the wallpaper will be neatly hidden underneath.

Advice: if you have a renovation in your apartment, then it is better to install the trims on the slopes from the Belgian sandwich panel after gluing the wallpaper yourself - it will turn out neater and prettier).

Installing accessories on windows

On final stage a double-glazed window is installed in the window frame and sashes are hung. Installation in progress additional accessories, fastening of additional fittings and components, such as: step ventilator, retainer, mosquito net, blinds, etc.

The window is ready. Upon completion of all work, an acceptance certificate is signed. In it, if necessary, the customer indicates his comments on the work performed, if any.

Almost immediately after completing all the work, the PVC window can be used. The exception is windows with large opening sashes, which are not recommended to be opened within 24 hours after the installation of the PVC window.

The plastic window is much better in functionality than the old ones wooden windows... If follow simple instructions for its care and operation, it will serve you forever.

Don't forget to remove the protective film from the outside of the PVC window!

According to GOST 30674 "Window blocks made of PVC profiles":

Deleting protective film from the front surfaces of the profiles should be done after the installation of products and the finishing of the mounting opening, taking into account that the duration of exposure to sunlight on the protective film should not exceed ten days.

If repair work is still underway in the room where the windows were installed, the protective film may remain on the product until they are completed. However, from the outside, the film should not be exposed to sunlight for more than 10 days.

The adhesive base of the protective film loses its properties under heat and UV exposure and can spoil the aesthetic appearance of the plastic profile.

General requirements for installation in accordance with GOST

GOST 30971-2002 “Seams of assembly units for joining window blocks to wall openings. General technical conditions»Put into effect by the order of the State Construction Committee of the Russian Federation from 01.03.2003.

Due to the need to adjust the design documentation for design and construction organizations, the transition period for the development of GOST was established until 01.07.2003. The republics of Azerbaijan, Kazakhstan, Kyrgyzstan, Moldova and Uzbekistan have joined the Russian norms.

What's new? New standards bring significant formalization of window installation and require numerous documents. Among them, it should be noted the need for each installation company to have "Instructions for the installation of windows", approved by local authorities, the need to develop assembly assemblies of windows for each facility under construction and coordination of assemblies with the customer, it is recommended to analyze the thermal fields, as well as the registration of certificates of delivery - acceptance of window openings before installation, acts of hidden works and certificates of acceptance of the completed installation of windows.

Of particular interest in the standards are the Appendices:

- Appendix A (recommended) presents drawings with examples of window installation;

- Appendix B (recommended) sets forth requirements for fastening windows in openings;

- Appendix B (mandatory) represents the actual requirements for the installation of windows in general and, in fact, is the main working document;

- Appendix D (recommended) describes the requirements for the method for calculating thermal fields (isotherm analysis).

In general, the Russian installation standards bring us closer to the standards adopted in Europe, and, in particular, in Germany.

GOST requires a large number of formalities from window firms and has more requirements for testing joint structures and materials used for them.

Formalization is justified by the fight against Russian negligence.

The testing of materials and seams in general is justified by the fact that until now in Russia there have been no detailed standards for installation at all, there is no accumulated scientific experience in determining the properties of installation materials and the quality of seams. Of course, for the consumer there is no need to know all the provisions of this GOST, this is the duty of professionals.

Without delving into the intricacies, we can talk about three basic principles of installing windows, which should be paid the closest attention.

Three layers of joint

The content of the main part of the norms is devoted to the rules for filling the mounting gap between window blocks and openings on the basis of the principle "from the inside is denser than from the outside." Each assembly unit must have three layers of sealing: outside - protection from climatic influences, in the middle - insulation, from the inside - vapor barrier. Can be used different materials for outer layers and different polyurethane foams, but, in one version or another, these three termination planes must be present.

Outer layer is designed to protect the insulation layer from moisture penetration into it, and must be vapor permeable in order for the insulation to be ventilated through it. That is, the outer layer must be waterproof and vapor-permeable.

These requirements are due to the fact that when moisture penetrates into the insulation, its thermal insulation qualities fall. The best way PSUL (pre-compressed sealing tapes) meet modern requirements for the outer layer. These are special mounting tapes that are glued to the window frame before installing it in the opening, and then, expanding, they fill all the leaks of the quarter in the opening.

With serious advantages: optimal construction physics and technological simplicity, they also have disadvantages. It is convenient to use these tapes in new construction when the opening has good geometry. But when replacing windows in old houses, when the slopes are uneven, and even more so, plaster, their use is difficult. Another drawback is that the plaster does not apply to the PSUL.

In limited form, it is possible to use silicone outside. In this case, certain rules should be observed: the thickness of the silicone layer should be half of the width of the joint to be filled, and the silicone should be glued only on two sides and work in tension, its other sides should remain free.

A sealant can be used when insulating an assembly seam. Although, it is not clearly spelled out in the GOST, but there is no ban on its use, no matter how much the supporters of mounting tapes want. An example of the use of silicone outside and inside the room is shown on node A.14 in GOST 30971-2002. It is unacceptable, of course, as you can sometimes observe on objects, just anoint with silicone over the foam - this is an imitation of the protection of the seam, but not the protection itself.

Central layer- heat insulating. Currently, polyurethane foams are used for its execution. It is best to use foams made specifically for window installations. These foams fill the joint evenly and do not need to be trimmed once they have hardened. Other foams, after the installation is completed, hang in shreds from the side of the room, and they are cut off, breaking the protective outer crust.

The inner layer- vapor barrier. Its function is to protect the insulation (foam) from moisture vapor penetration into it from the side of the room. For these purposes, when plastering slopes, vapor barrier tapes, mainly based on butyl, are used, as well as paint vapor barriers for moisture-resistant gypsum plasterboards. It is possible to use silicone according to the rules mentioned above.

Lack of cold bridges

Assembly seam- this is the node where the joining of the wall and window structures takes place, which have completely different properties, including in terms of heating technology. And it is important to execute the knots in such a way that cold bridges do not appear on the window slopes.

Basically, the problem of cold bridges is the problem of single-layer wall structures that were used in houses of the past (solid brick, expanded clay concrete, etc.). In this case, the weak zone is the wall itself around the window frame due to its low resistance to heat transfer. An area with a surface temperature below the dew point appears on the slope. In this area, firstly, there are high heat losses, and secondly, condensate falls out on it. If moisture condensation on the slope occurs frequently, then later on these places can form a fungus (mold). The same applies to quarter-cut openings. In their absence, the danger of cold bridges seriously increases, and here you should especially carefully consider the heating technology of the junction nodes.

An important recommendation is to use window frames with a width of at least 130 mm in the absence of quarters. With a narrow window frame, high-quality sealing of the seam is difficult and there is a high probability of cold bridges. The options given in GOST with false quarters from the corners or from the platband are possible only if there is external plaster, and still remain problematic from the point of view of heat engineering.

If there is an effective insulation in the wall ( mineral wool or non-combustible polystyrene foam), the window should stand either in the plane of the insulation, or behind a quarter of the insulation. In walls where aerated concrete is combined with external cladding and brick quarters, as a rule, cold bridges also do not arise due to the good thermal properties of aerated concrete.

Fastening the window unit in the opening

The specificity of plastic windows is that they have significant thermal linear expansion. That is, when the windows are heated by the sun's rays, the bars of the box and sashes increase in size. As calculated thermal expansion values for windows white 1.5 mm per 1 running meter should be used, for colored windows - 2.5 mm per 1 running meter (the difference in thermal expansion is due to the fact that white window profiles heat up much less than colored ones).

In accordance with this factor, the window is fastened to the wall. The corners of plastic windows must remain free, the extreme fasteners are placed at a distance of 150 mm from the inner corners of the frames. The rest of the fasteners are installed along the entire perimeter with a step for white profiles not more than 70 cm, for colored ones not more than 60 cm. Near the imposts, fasteners are also placed at a distance of 150 mm from the corner. The gap between the box and the wall must be at least 15 mm. This is due to both thermal expansion of the windows and the fact that it is very difficult to fill a thinner seam with foam insulation evenly.

Bearing blocks are placed under the lower corners of the box and under the imposts. The pads are also placed from the sides as follows: if you look at the window from the inside, then with one pivot sash, the pads are placed on the side opposite to the hinges at the top and on the same side as the hinges below. With two flaps, respectively, four pads are placed.

Schematic diagrams of the nodes of the junction of window boxes to the walls

1 - window board;

2 - foam insulation;

3 - vapor barrier tape;

4 - flexible anchor plate;

5 - support block for the window sill;

6 - plaster mortar;

7 - dowel with a locking screw;

8 - an insert made of antiseptic lumber or a leveling layer of plaster mortar (recommended only for the lower unit);

9 - waterproof vapor-permeable tape;

10 - noise-absorbing gasket;

11 - drain;

12 - insulating self-expanding vapor-permeable tape (PSUL);

13 - sealant in a thin layer

1 - foam insulation;

2 - insulating self-expanding vapor-permeable tape (PSUL) or vapor-permeable mastic;

3 - frame dowel;

4 - sealant;

5 - vapor barrier tape;

6 - interior slope finishing panel;

7 - plaster leveling layer of the inner slope.

Thermal gaps must be taken into account especially carefully when designing large-sized glazing elements: when making bay windows, showcases, glazing to the entire floor height. These are three basic principles when installing modern windows, although, of course, there are many nuances and subtleties that depend on various designs walls and from the materials used for sealing the seam. And - as we said at the beginning of the article - the human factor is very important - the responsible and high-quality work of the installers.

When can you install windows

With the enactment of Moscow Law No. 42 "On Silence", disturbing the peace of the neighbors is an administrative violation. Please carefully read our instructions for conducting noisy work in order to comply with the requirements in force in Moscow and the Moscow region in various buildings.

How much is the installation of windows in accordance with GOST

The cost consists of two components: the cost of work (hours) and materials.

The assembly seam will comply with GOST for the installation of windows, using both expensive and economical materials. The use of one or another will affect the stages (duration) of work and the final cost of installing windows.

Video instruction for the installation of plastic windows